Ultimate Guide to High-Power Variable DC Power Supplies(2026 Industrial Standards)

The definitive resource for engineers demanding precision, automation, and reliability in modern power systems.

In the rapidly evolving landscape of electronics manufacturing and R&D, the demand for precision and stability has never been higher. As we move into 2026, the humble power supply has transformed into a sophisticated, intelligent node within the automated test ecosystem.

Whether you are managing a large-scale burn-in room for semiconductor aging or setting up a precision R&D laboratory, the stability of your voltage source determines the validity of your test results. Unlike hobbyist equipment, modern industrial variable dc power supplies are engineered to deliver clean, ripple-free power under extreme load conditions, ensuring the safety and reliability of your Device Under Test (DUT).

In this comprehensive guide, we explore the architecture, applications, and selection criteria for high-end programmable DC power systems.

The Evolution of Programmable Power

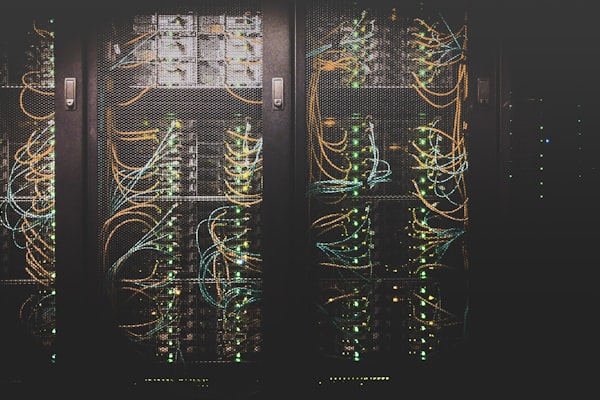

Gone are the days of simple analog knobs. The 2026 standard for industrial power supplies centers on automation and connectivity. High-performance rack-mount units are no longer just energy sources; they are active components in Automated Test Equipment (ATE) systems.

Higher Power Density

Delivering up to 15kW in a compact 3U chassis size, utilizing advanced GaN (Gallium Nitride) switching topology.

Fast Transient Response

The ability to recover voltage stability within microseconds during rapid load changes—critical for testing EV components and aerospace avionics.

Digital Integration

Native support for SCPI commands via LAN (LXI), USB, and RS485 interfaces, allowing for seamless integration into LabVIEW or Python-based control scripts.

Critical Applications in Industry

Production Line Burn-In

For electronics manufacturers, burn-in testing is the final gatekeeper of quality. A variable DC power supply in this scenario must run at 80%-100% load for 24 to 72 hours continuously.

Laboratory & R&D

Engineers require "clean" power. Excessive ripple and noise can interfere with sensitive signal measurements. High-end programmable supplies offer linear-like low noise performance.

Electroplating

In chemical processing, precise current control (Constant Current Mode - CC) is vital for coating thickness uniformity across industrial components.

Explore Our In-Depth Resources

Technology Deep Dive

Understand SCPI, Hybrid Architectures, and 2026 protocols.

Burn-in & ATE Solutions

OVP/OCP protections for unattended automated testing.

2026 Review & Rankings

We tested the top rack-mount models for ripple and noise.

Price Guide

An honest analysis of industrial power supply costs and TCO.

Sourcing Guide

Manufacturer Direct vs. Distributors – Where to buy?

Key Technical Specifications to Watch

When evaluating a programmable variable DC power supply, pay close attention to these four specs:

| Parameter | 2026 Standard |

|---|---|

| Load Regulation | < 0.01% + 2mV |

| Ripple & Noise | < 5mVpp |

| Programming Acc. | < 0.05% + 10mV |

| Response Time | < 1ms |

Ready to find the right power supply for your application? Browse our complete catalog with real-time stock availability and competitive pricing.

Visit for Online Stock & Pricing